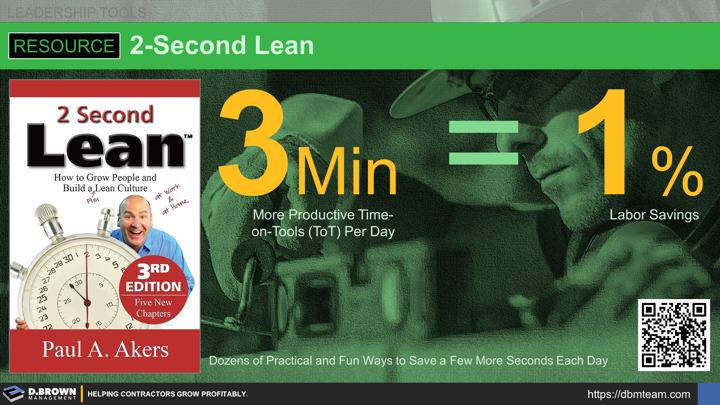

What if you could get everyone on your team in the habit of (1) seeing waste, and (2) taking the initiative to eliminate one small bit of waste every day?

2 Second Lean heavily resonates with the crafts people and field supervisors in construction companies. It is also easily adopted by all other front-line and managers throughout the company from estimating through PMs and accounting.

It is a great tool to use to start changing your culture, improving productivity, and making continuous improvements to your entire value stream.

- 2 Second Lean Book: Buy in bulk for $5 each - English and Spanish

- Lean is Simple: Talk for the Lean Construction Institute

- Lean at DPR Construction

- Walters & Wolf Tour: Glazing contractor that implemented 2 Second Lean

- Daily Huddles: Building a culture of continuous improvement

- FastCap 2017 Improvements: Great summary of key improvements to see the culture

- Kaizen Improvements: Great example of using a stopwatch and creative talent to improve cycle times significantly in 2011. You can see the continued improvements to this workstation in the 2017 improvements video. How could you apply this in the field?

- More Videos from Paul Akers / FastCap

CRITICAL NOTE: These small continuous improvements are not a substitute for strategic decisions, value stream design, standards, or major workflows throughout the company. They are a major enhancement and will create healthy habits that allow teams to adapt changes to strategy, value stream, standards, and workflows much more effectively.

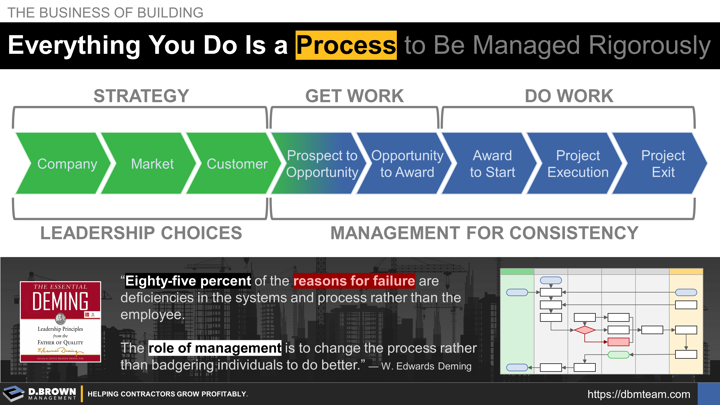

Responsibilities for these are integrated but start at each of the following levels:

- Strategic Choices including clarity on what the business will not do are the direct responsibility of the board (owners), CEO, and President. These become increasingly more important as a contractor grows.

- Major Value Streams aligned with the strategic choices and a viable Business Model defining high-level standards is the direct responsibility of senior leadership including President, COO, CFO, and EVP levels. For smaller contractors, this may all come back to the owner who is serving in all these roles.

- Workflows outlining the sequencing and relationship of key tasks, decisions, meetings, and quality control (QC) points across functional areas of the business is the direct responsibility of the EVP and VP levels of the organization. These are integrated with the value stream, business model, and standards. These will include more detailed business models and standards required for performance.

- Functional area workflow details and procedures for each task or decision along with the templates, tools, and checklists are the direct responsibility of the roles responsible for managing that functional area. An example may be the Controller managing the accounting function or Chief Estimator managing the estimating function.

- Front-line managers and workers will assist in these and may even create them fully as part of their ongoing development, but it is not their direct responsibility. Their primary continuous improvement tools are outlined very effectively in 2-Second Lean.

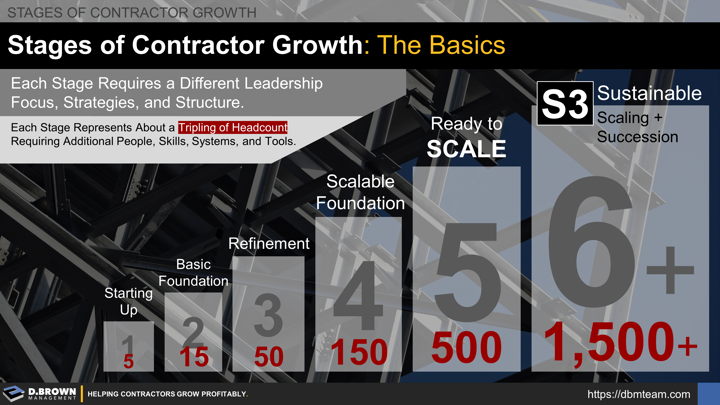

It is important to note that all these layers don't likely exist until a contractor is fully at Stage 5 or above in growth. As they are scaling up to this size, the direct responsibility moves up. Attempts to "Pull Up" may occasionally result in breakthrough performance but most of the time just results in increased stress with zero increase in performance.

Please contact us to learn more about our training, coaching, and advisory services to help contractors effectively navigate all these stages of growth.