Those that want to continue sustainable growth must manage every aspect of their talent management processes with the same rigor they would manage a fast-track project with $100K per day in liquidated damages.

On November 15th, Katie McConnell and David Brown kicked-off the first of a three-part series focused on talent.

- Diagnosing the Biggest Talent Bottlenecks for CFMA Sacramento Members

A few interesting takeaways from the first session were:

- When asked what their hiring challenges were, nearly 100% of the audience cited external market factors, which included the shortage of talent. To begin solving the problem, we must first start looking inwardly at the areas they can control and, more specifically, those that matter.

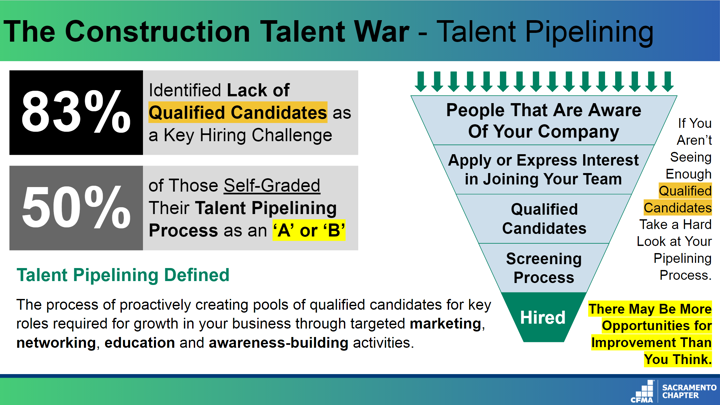

- Of the 83% of people who stated their challenge was not enough qualified talent, 50% of those also rated their Talent Pipelining process as effective (an ‘A’ or ‘B’). This is a little bit like stating your sales process is effective but not achieving the sales you want.

The next step in solving a problem is to recognize that we may be looking at our internal processes and capabilities with more rose-colored glasses than we think. We actually may not even know what we don’t know.