Contractors must continuously improve their operations in 3 ways to remain competitive and grow profitably:

- Efficiency - Doing things with less waste improving quality, speed and cost

- Capabilities - Providing more services such as offering more advanced preconstruction services

- Capacity - Ability serve growing customers; possibly in multiple geographies

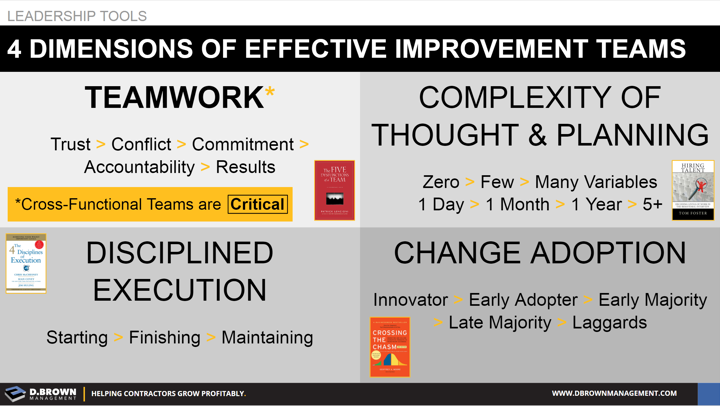

To accomplish this contractors must identify areas of focus then put together effective improvement teams. There are four major dimensions we look for when putting together these teams:

- Teamwork - Can they effectively work together?

- Complexity of Thought & Planning - Everyone is different; does the team have the right mix to solve the problem? Do you have an opportunity to develop capabilities in high-performers through the team?

- Disciplined Execution - Some people are great starters while others are amazing finishers and if you don’t have some disciplined maintainers on the team then any short-term gains will be lost quickly.

- Adoption of Change - Everyone is different in different circumstances and a mixture is critical for making lasting improvements.

What’s the #1 area you need to improve in your company this year?

Do you have the right team?

Are they meeting regularly?

Are they committing the right resources?