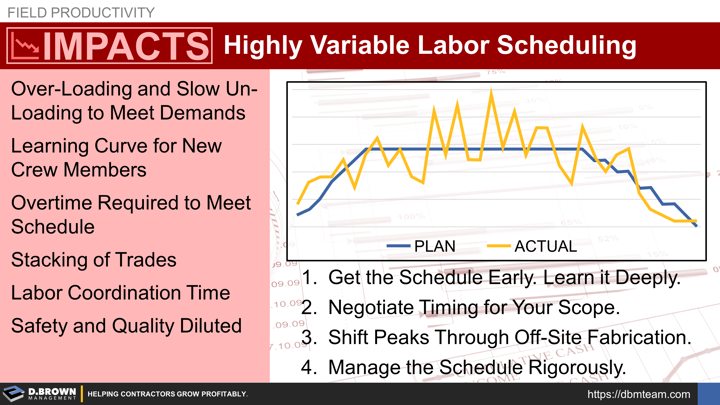

One of the biggest impacts to labor productivity is having a schedule that requires large variations in labor. The most ideal situation is to have a steady ramp up, stable crew size during peak production followed by a steady demobilization.

No project will be perfect and impacts to highly variable labor requirements include:

- Overloading the project to meet demands resulting in too many people during downtimes, which then lowers productivity.

- Learning curve for new team members coming on and off the project. Studies show that productivity can be impacted by as much as 10% during the first week for a craftsperson learning a new project.

- Overtime required to meet the schedule. Not only will you have the increased cost per hour, but you will experience a decrease in productivity and safety. Four weeks at 5-10’s will impact productivity by 20%.

- Poor scheduling often goes hand-in-hand with stacking of trades which can cost another 10-50% decrease in productivity for those areas.

- There is an increase in the coordination time it takes to move manpower on and off the project which has a direct cost as well as an indirect cost from dilution of management.