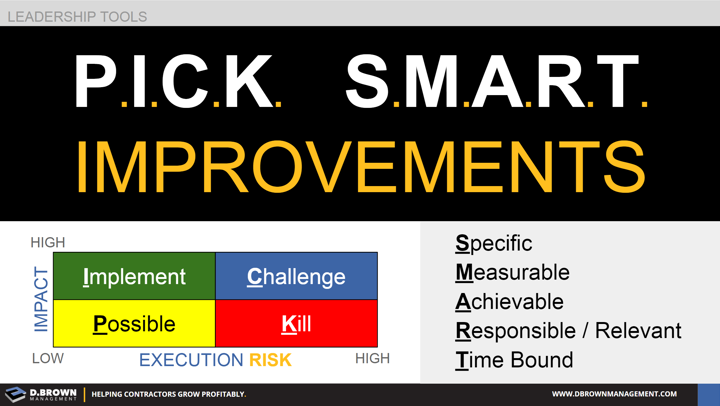

There are a couple tools that can be used to align the team around the best utilization of resources:

- Brainstorm the potential improvements with a cross-functional team. This is about creating alignment as much as prioritization.

- Consolidate your list down into a manageable number of items - no more than 20.

- “Force Rank” them first in order of impact highest to lowest then on execution risk to distribute them into the four quadrants. This is harder than it seems. Try having several people do it independently then discuss and decide.

- Think about this as a tool that is continuously used - what might be in the “Kill” or “Challenge” categories today may be in the “Implement” category in a few months.

- Starting in the “Implement” quadrant begin identifying specific improvements that can be made within the next 1-30 days.

- Your focus is on making progress towards your goal - beginning to climb the mountain. Your whole path will become clearer as you start the climb.

- If the improvement item is too big break it down making it more specific.

- Set a regular weekly meeting rhythm to review progress, identify new items, adjust and keep climbing.

This seems easier than it actually is and it takes a lot of energy to keep progress moving forward. As you gain momentum with the team you can continue to refine the process.