We'll start with some basic metrics to pragmatically quantify the problem and then move to some underlying root causes for context, wrapping up with some strategies that can be put to use immediately, though the results will lag.

The Magnitude of the Problem and Foundational Assumptions

Qualifier: These numbers are not meant to be exact. This is only a model to illustrate the rough magnitude of the problem and timing so leadership teams can better plan and allocate resources.

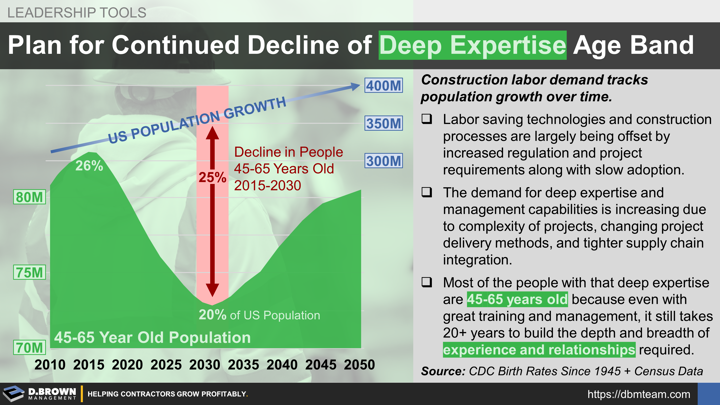

- Construction labor demand tracks population growth over time.

- Labor saving technologies and construction processes are largely being offset by increased regulation and project requirements along with slow adoption.

- The demand for deep expertise and management capabilities is increasing complexity of projects, changing project delivery methods, and tighter supply chain integration.

- Most of the people with that deep expertise are 45-65 years old because even with great training and management, it still takes 20+ years to build the depth and breadth of experience and relationships required.

- We reached a peak in 45-65 year-old population in 2015 representing about 26% of the US Population.

- We will see this age band continue to decline through 2030 where it hits 20% of the total US population.

- This rate stabilizes and starts to improve through 2050 but won't be back at 2015 levels any time in the relevant planning time horizon for a contractor.

- The source data for pragmatic quantification was from CDC birth rates since 1945, census data, and BLS construction employment data.

- Immigration numbers and estimates are not included because the age range data was not clear enough. Immigration improves this gap some but for order-of-magnitude and decision making, this was close enough.

Looking at the Primary Underlying Causes and "Talent Funnel" and Timeline at a Macro Level

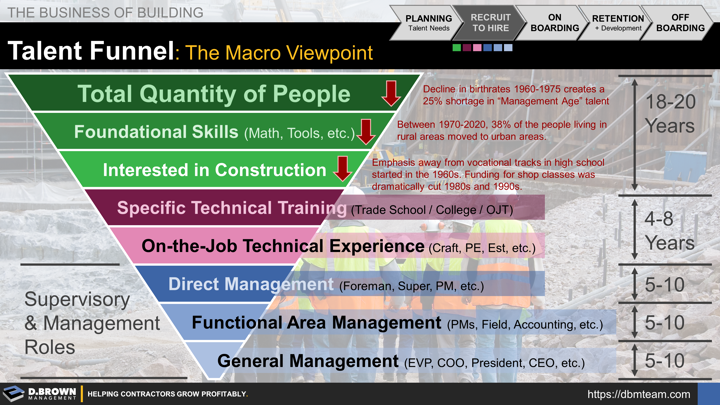

The key drivers to the talent shortage that contractors are feeling across the board are:

- There was a massive decline in birthrates between 1960-1975, which is creating that 25% dip in the 45-65 year-old population between 2015-2030. This impacts all industries.

- Between 1970 and 2020, 38% of the people living in rural areas moved to urban areas, impacting both the desire to enter the construction industry as well as knowledge about tools and building that are learned from a young age when growing up in rural areas.

- There was an emphasis away from vocational tracks in high school starting in the 1960s. This was a strategic change to build the workforce required for other industries like technology. Funding for shop classes was dramatically cut in the 1980s and 1990s. Funding and emphases on vocational training is changing with the shifting needs of the US, but these changes are slow.

Strategies and Tactics for Contractors to Mitigate This Challenge and Thrive Long-Term

- Develop market strategies that allow you to have a better ratio of experienced to less experienced people on projects. Know that this will create a bigger problem if it is not paired with talent development strategies.

- Develop market strategies and business processes that allow for higher margins which will allow you to increase compensation beyond what other contractors can sustainably pay. Know that compensation alone WILL NOT solve a massive shortage in supply just like you can't offset a 25% decline in oil supply through higher gas prices.

- Look for creative ways to joint venture or partner with other companies that can create synergies in your capabilities and capacity. This may include mergers and acquisitions.

- Change your workflow and organizational structure to ensure that those with deep expertise are using them most of the time with supporting roles handling any tasks requiring less expertise. This can create hand-off and coordination problems if not managed right but underutilization of those expertise would be the same as an underutilized expensive piece of equipment on a jobsite.

- Change your workflows, organizational structure, and staffing plans to accelerate development of younger team members. This will cost more in the short-term but is the only strategy for the mid and longer-term. Examples might include attaching a Field Engineer (or two) to each of your highly experienced Superintendents and General Foremen with a structured development plan for them to learn at an accelerated rate.

- Develop structured "Off-Boarding" plans for your most experienced team members so they can phase out of daily operations and into training, coaching, and mentoring roles part-time until they move fully into their "Retirement Masterpiece."

- Invest in training your front-line managers and supervisors the principles of effectively breaking down a task into individual steps and then training and managing others. Study the Training Within Industry program from WWII, especially the Job Instruction (JI) training manual. We dramatically increased production while pulling about 12 million people for military service out of our 55 million person workforce at the time - a 22% decline. The US nearly doubled output during that same period. Toyota still uses most aspects of the Job Instruction manual relatively untouched. People are people and though the tasks and tools have changed some, the principles of teaching and learning have not.

- Invest heavily in labor saving technologies. Not all of them will work out, and few work out the first time. It is the continual exploration, selection, experimentation, implementation, and adoption that creates long-term labor savings allowing maximum leverage of your deep expertise.

There are no magic bullets for this. Each of these is very nuanced and not easy to execute. Please do not hesitate to contact us. We will freely share anything we can about specifics that could help your situation, including the challenges of implementation.