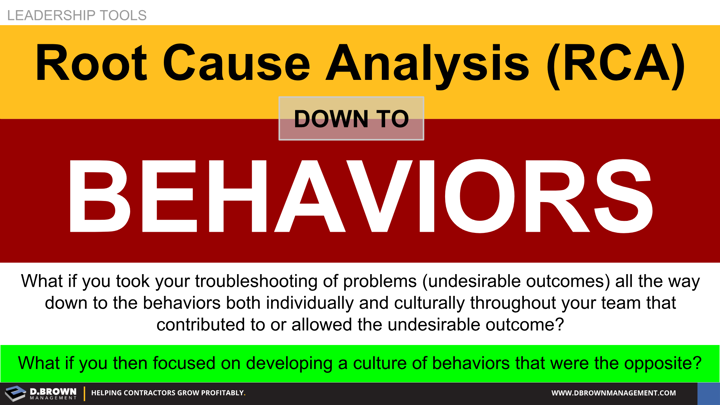

What’s important is that a team develops the skills and routine habit for continuously improving (PDCA). When troubleshooting a problem it’s important to do Root Cause Analysis (RCA) so that you aren’t just putting a band-aid on it.

Root Cause Analysis; also called “5 Why’s” dives into

- What happened? The undesirable outcome.

- How did it happen? Process, controls, etc.

- Why did it happen? Contributing factors including culture, competency, behaviors, etc.

There are lots of elements to RCA as NASA outlines.

RCA is a major element of the Last Planner System and the Rapid Learning after evaluating the PPC on the weekly work plan.

As you are doing your own Root Cause Analysis look at the underlying behaviors that allowed the problem to happen or heavily contributed to it.

If you do this a half-dozen times looking back at project or company problems you will start to see recurring themes in behaviors that contributed to an undesirable outcome.

After you get there do a few things:

- Look at your values. Are they defined as behaviors - “I will…” type of statements?

- Are they the opposites of the bad behaviors that contributed to the problems?

- Do you have a good method of identifying these desired behaviors in your hiring process?

- Do you have a good feedback system to reinforce the right behaviors?

- Are you leading by example?