Even tiny details that are not coordinated or communicated effectively cause delays, rework, performance and warranty issues.

The good thing about even a bad project is that it eventually ends and the team is on to the next one.

Unlike a project; the routine processes you use every day in your business don’t have an end point therefore the continuous improvement should be part of your routine as well. Poorly coordinated people, processes and technology become exponentially more inefficient as the business grows eroding profits, morale and customer satisfaction.

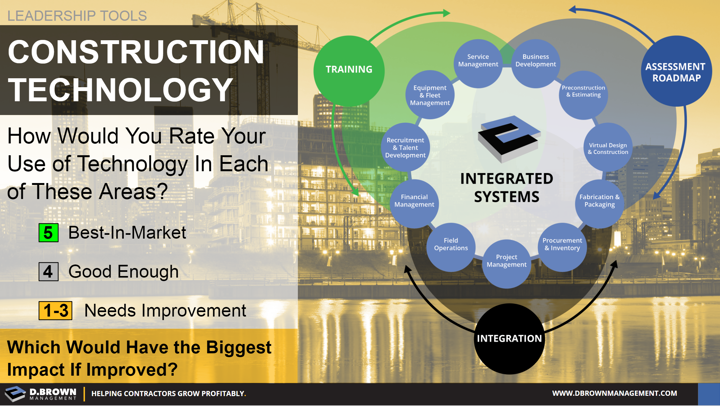

- Assessment & Roadmap: Regularly look across your whole business rating your various systems then identifying your #1 bottleneck or opportunity. Be pragmatic in your assessment and quantification. Be conservative and flexible in planning your roadmap.

- Integration: Focus on your #1 bottleneck or opportunity integrating the related process and technology to add maximum value for the next 2-5 years. Beyond that there are too many changes coming.

- Training: If you fail to invest enough in training your current team and effectively integrating new team members as you grow or there is turnover your return on investment will be impacted and start to decline.