A deep understanding of this value stream at various levels of detail down to actual installation steps is the foundation upon which major productivity improvements can be made.

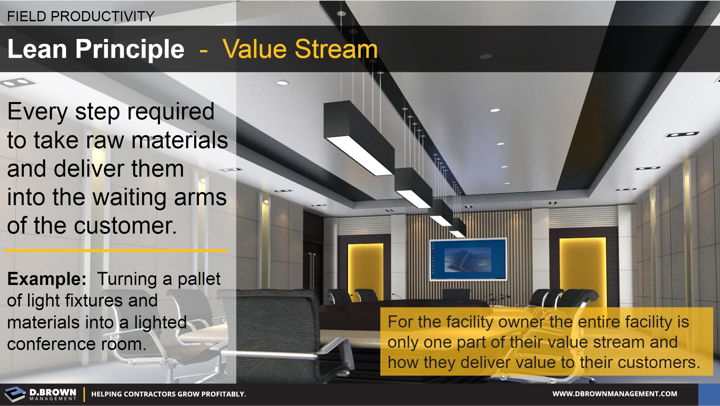

As an example consider every step required to put lighting in a conference room - these are just the highlights:

- Initial design requirements

- Quotes from distributor for estimating

- Submittals and approvals

- Ordering, tracking and receiving

- Moving around jobsite to work area

- Installation

- Inspection

- Training of the customer

- Punch list

This is the highest level and if you mapped out each of those in another 5-25 steps you would start to see a clear picture of what it really takes to install a light fixture in a conference room.

Start at the highest level - what can be cut out, reduced or sequenced differently?

Look at the details - can you use 2 screws instead of 4? 50% cost savings at that step!

Remember that the customer just wants light - could a skylight or more windows reduce the lighting need at the design stage?