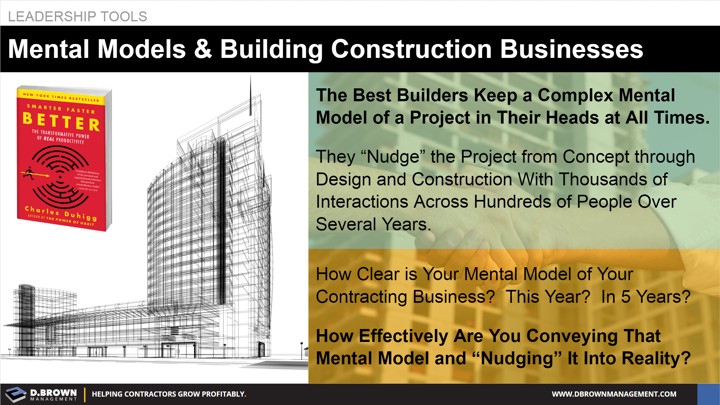

This complex 5D mental model is then constantly kept updated. Through thousands of interactions with hundreds of people over years they “nudge” the project from concept through construction completion.

They make lots of mistakes but what keeps the project on-track is that they know what’s not fitting their mental model and they adjust quickly. They have rigorous processes for managing design revisions, requests for information and a submittal process to ensure they are getting what they really want. They have many routine meetings, planning and communication rhythms.

Building a construction business is no different; just more complex and (hopefully) continuing on for many decades. It is critical for leaders at all levels within a contracting business to develop detailed mental models of the business as it operates today and as they want it to operate in the future.

They must engage people who will challenge every aspect of that mental model just as a building design is challenged to make it better, more cost effective, faster, etc.

This is where an unbiased but experienced 3rd party facilitator can really add value.

Learn More:

- Smarter, Faster, Better Book

- Charles Duhigg Mental Model Explanation