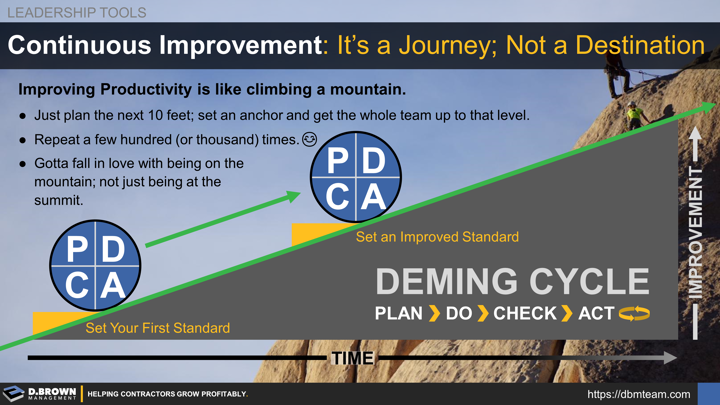

It must be embraced as a journey and not a destination. It must be embraced as a continuous learning process. It must be made into a game so that people clearly see what winning looks like and fall in love with the process.

Growing a contracting business is like climbing a mountain. Trying to master plan every detail won’t work. There is no perfect playbook that fits every contractor and every team. Like climbing a mountain, the best thing you can do is create a reasonable plan, create some contingency plans, train yourself and your team hard, and then get to work.

Make your big strategic decisions about direction knowing that they aren't set in stone. Get clarity around the standards that you currently have in place with the knowledge that they will always be evolving.

Just plan the next 10 feet, set an anchor, and get the whole team up to that level. Repeat a few hundred (or thousand) times. You and your whole team gotta fall in love with being on the mountain and not just being at the summit. You are only at the summit for a moment in time before you need to get climbing to the next one or you slip back down into a valley and need to climb back up. Keep your team aligned while you climb.

PDCA is an acronym for Plan, Do, Check, and Act and can be traced back to Walter A. Shewhart in the 1920s and W. Edwards Deming who applied it to management practices in Japan in the 1950s. It is an integral part of the Toyota Production System (TPS) and the body of knowledge called "lean" including Lean Construction.

Over time, people have emphasized different aspects, such as changing the Check to Study (PDSA) to put more emphasis on really analyzing things before acting or preceding PDCA with Observation to understand what you were planning for. In all cases, the principle remains the same.

Contractors can look at PDCA in several levels:

- Strategic market choices including experiments.

- Business planning and execution using tools like Objectives & Key Results (OKRs).

- Installation standards at the task level. As an example, field productivity comes down to cutting seconds out of minute-long tasks or steps in a task.

Standards - The Foundation of Continuous Improvement:

"Without standards, there can be no improvement." - Taiichi Ohno (Toyota Production System)

As contractors navigate growth, there will never be a perfect plan or perfect standards.

An often overlooked element of the Plan, Do, Check, and Act (PDCA) process is that standards form the foundation. These standards start out as simple and evolve as a contractor navigates the various stages of growth. The broad stages of standard development are:

- Subjective (Individual Judgment): A person simply making a call as to "Good" or "Bad" on outcomes and knowing how to achieve a "Good" outcome. This is where all standards start. This is where the majority of the standards and knowledge in a contractor lives. These standards fall into the category of "Tacit Knowledge" and even with the proliferation of data centers across the world, it is still estimated that 95% or more of the world's knowledge is only held in the heads of the people living in it.

- Metrics (Outcomes): Defining clear expectations on outcomes whether it is profitability as compared to industry benchmarks or standards for field production. The first place a contractor typically uses this level of standard is with the estimating units and production rates they bid with. Example - install 4 units per hour. Metrics may also be schedule driven, such as the month-end financial calendar driving dates for billings, payables, job projections, and ultimately, financial reports completed and distributed. Metrics can be defined as both an overall outcome (lagging metric) and the interim metrics to get there (leading metrics) as shown in this cash flow example.

- Procedures (How-To): The next evolution in standards comes from taking the tacit knowledge (subjective standards) about the best way to do something and turn it into explicit knowledge defining every step required to perform a task including tips, tricks, troubleshooting, and when to escalate a problem. While there are different technologies including use of wikis, video, and Learning Management Systems (LMS), the basic principles of building a good procedure and training someone to perform consistently hasn't changed in the last hundred years. The Job Instruction (JI) program from WWII demonstrates this perfectly.

- Variability Ranges: No matter how good the procedure is, there will always be variability in the outcomes (quality, cost, schedule). These variability ranges or tolerances are part of every specification because there is a point of diminishing returns of driving toward zero variation. This is not a license to be sloppy but rather a reminder to study the procedure being executed by various people in various conditions and at different times to understand the variations. You can then understand what the return-to-cost ratio is for further improvements. Part of the process of setting these ranges is a Time and Motion Study (10 min intro video). Note that a Time and Motion Study is structured in a very different way than a Work Observation or Gemba Walk. The Time and Motion Study will get you to the very specific data you need for analysis, feedback, and improvement. Think about specific feedback to estimating to adjust company standards for a particular type of installation.

- Workflow (Connections): This defines how all the individual task level procedures (#3) and metrics combine together to create a highly functional system. Think about The Contractor Business Model as a high level starting point. Contractors that have scoreboard outcomes consistently 2-3 times industry benchmarks don't just have individual task efficiency but have system level effectiveness. Think about estimating units being fully aligned with field productivity and internal equipment costs. This includes a range of formats such as value stream, flowchart (change order example), responsibility matrix, and clear job role descriptions. These have a hierarchy and must be integrated to ensure value delivery to the customer (all levels).

- Management (QA/QC + Escalations): The final stage of standards is having clearly defined standard work for managers including how they check for quality outcomes (Quality Control - QC), how they check to ensure the procedures and workflows are being followed (Quality Assurance - QA), and clarity on what problems (variations) should be escalated, to who, how, and by when. Research "Leader Standard Work" (LSW) for how to create better systems for supervisor and manager roles including synchronized and standard timeframes for doing certain things. These two short videos explain the concepts of LSW very well. Please look past the production and presentation focusing on the content. Leader Standard Work Tips & Tricks by Drew Locher.

REMBEMBER:

- For a contractor at any stage of growth, 95% of all the tasks required to make the machine work should be at stage 1 - subjective standards and tacit knowledge.

- There will be a handful of tasks that are very high frequency, such as certain field installation tasks where saving even a few seconds per cycle time or small percentage reductions in rework will add up to a huge savings. These are the ones that you will want to concentrate building your standards to higher levels up through stage 6 including LSW.

- There will be a handful of tasks that are very high leverage such as your opportunity go/no-go, cost and quantity estimate review, proposal prep, and project planning. Pursuing and winning just one bad opportunity or going forward with just one bad quantity and cost estimate can cost hundreds of thousands of dollars or more. These are also the places that you will want to concentrate on.

Collectively, all of these can be considered part of the "Management System" which is the final strategic question that must be answered by every contractor and at every stage of growth.

Brief History of the PDCA (Plan, Do, Check, and Act) Process:

"Eighty-five percent of the reasons for failure are deficiencies in the systems and process rather than the employee. The role of management is to change the process rather than badgering individuals to do better.” - W. Edwards Deming (Book - The Essential Deming).

The PDCA (Plan-Do-Check-Act) process, also known as the Deming Cycle or Shewhart Cycle, is a systematic series of steps for gaining valuable learning and knowledge for the continual improvement of a product or process. It has its roots in scientific management and has become a cornerstone of continuous improvement efforts, particularly in manufacturing and quality management. Here's a brief history of the PDCA process:

Walter A. Shewhart (1930s): The earliest origins of the PDCA cycle can be traced back to the renowned statistician and engineer Walter A. Shewhart. While working at Bell Telephone Laboratories in the 1930s, Shewhart developed the concept of the control chart and began laying the groundwork for statistical quality control. He introduced the idea of "specification-production-inspection" which can be seen as a precursor to the PDCA cycle.

W. Edwards Deming (1950s): Dr. W. Edwards Deming is often credited with popularizing the PDCA cycle, especially in Japan after World War II. While Shewhart was his mentor, Deming expanded and refined these ideas and introduced them to Japanese industry during the post-war rebuilding period. Deming emphasized a systematic approach to problem solving and continuous improvement. Although Deming referred to it as the "Shewhart Cycle" in honor of his mentor, in many circles, it became popularly known as the "Deming Cycle".

Adoption in Japan (1950s onward): After World War II, as part of the recovery efforts, Japanese industry sought to improve its quality and productivity. Influential Japanese business leaders and scholars attended Deming's lectures and adopted many of his teachings, including the PDCA cycle. As a result, PDCA became deeply ingrained in the Japanese approach to quality management and continuous improvement, leading to the development of techniques such as Kaizen.

Integration into Quality Frameworks (1980s onwards): The PDCA cycle was further popularized in the West through its integration into various quality frameworks, methodologies, and standards, such as ISO 9001 and Total Quality Management (TQM).

Modern Adaptations: Today, PDCA is recognized as a foundational concept in various domains, including lean manufacturing, Six Sigma, software development, and more. Its iterative approach to problem solving and continuous improvement is widely regarded as an effective methodology to drive positive change and innovation.

In essence, the PDCA process has evolved over the years from its early conceptualizations by Shewhart and refinements by Deming, to its widespread adoption and integration into modern business practices and quality management systems around the world.

As with all knowledge, the principles have been around for a very long time. The magic is in the application, and especially the application at scale which requires consistent and thorough transfer of knowledge. For example, Deming observed "Check" as being misinterpreted as merely inspecting and measuring outcomes (QC) without delving deep into understanding why those outcomes occurred. "Study" emphasizes a deeper analysis, helping to ensure that improvements and changes are based on a comprehensive understanding of the process. He tried to introduce the variant PDSA (Plan, Do, Study, and Act) but that hasn't yet fully caught on.

The important principle is to have a person with the right level of training, tools, and experience doing the "Check" aspect of PDCA looking the outcomes, the process, and how it fits into the broader workflow adding value to the customer. This is where "Root-Cause Analysis" or RCA ties into PDCA.

Recommended continued reading for deeper understanding of the PDCA cycle and how to prioritize where to focus:

- The Toyota Way (Audible) Understanding their 14 principles will help you see connections to any business or project.

- The Goal (Audible) Figure out your constraints and bottlenecks before applying resources with this introduction to the Theory of Constraints (ToC).

- The Essential Deming (Audible) Learn the underlying management principles that set the foundation for many of today's best practices in managing the manufacturing and construction process.

While the concepts are relatively simple, the application requires discipline including choosing what level is appropriate given the task, the stage of growth, strategies, business model, and the development phase of the management team. This is where an experienced but unbiased third party can be extremely valuable.

Please contact us to confidentially discuss your specific vision, team, and situation. We will always share freely with you anything we know that can help.