An improvement of a few minutes per day to actual installation time compounded monthly is worth about $800K per year for a $25M contractor. What is it worth to you?

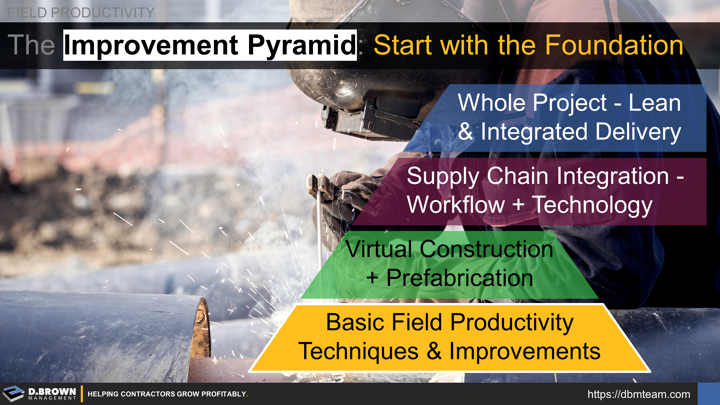

Look at improvements to field productivity as 4 major stages of a pyramid and start with the foundation:

- Basic field productivity techniques and improvements focused on creating the “Perfect Day” for the field by relentlessly focusing on the 6 Pillars of Productivity. This foundation will amplify every other layer of the pyramid.

- Virtual Construction and Prefabrication when done correctly will dramatically improve productivity. Done incorrectly they will create an unbelievable amount of stress on the team as well as waste.

- Supply Chain integration at the levels of risk management, workflows and technology can eliminate significant waste while improving the schedule.

- From the project owner and general contractor side integrating all trade partners and leveraging lean construction techniques is really the top of the pyramid. Like all other layers, if done well the improvements are amazing. Done poorly and failures are just as big.