This has become even more challenging with the craft labor shortage. Training field supervisors and the entire project team the tools, workflows and behaviors that will improve production is a big part of the solution.

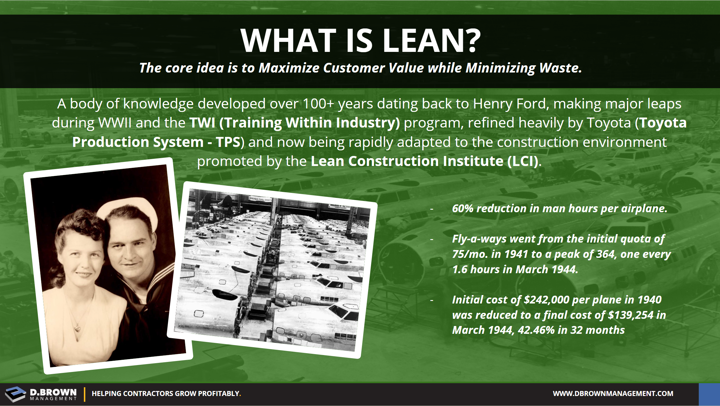

The Training Within Industry program used during WWII can be viewed as the most massive vocational supervisory training and process improvement program ever rolled out. Most of the principles are as applicable to solving our field productivity and talent shortage problems today as they were then. Every leader in the construction industry must become a student of these prior lessons learned then figure out how the best ways to apply them to their teams and companies.

Read more: Training Within Industry: Job Instruction

If you want to learn more about the best resources and talent we have found for helping contractors improve labor productivity contact us. That is one of our employees grandmother in the picture who was trained very quickly to build airplanes at the Boeing plant in Washington while her grandfather was serving on the USS Lexington.