With all the new technologies readily available in the construction industry, why are more contractors and project owners seeing dramatic increases in inefficiencies?

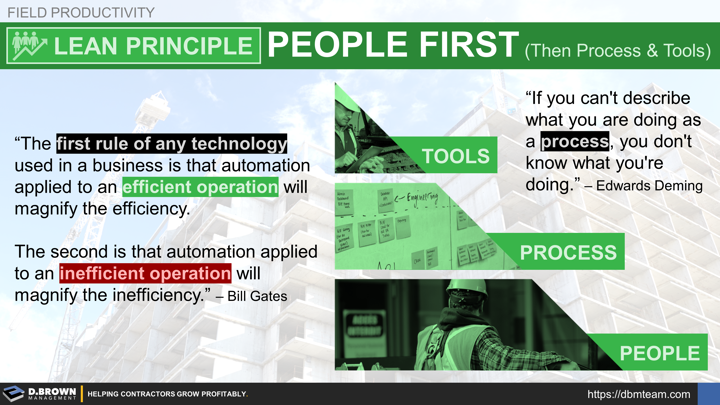

Wisdom from Bill Gates About Technology

“The first rule of any technology used in a business is that automation applied to an efficient operation will magnify the efficiency.

The second is that automation applied to an inefficient operation will magnify the inefficiency.”

This applies to any tools - whether it is a backhoe, cordless bandsaw, or software.

Wisdom from W. Edwards Deming About Process and People

“If you can't describe what you are doing as a process, you don't know what you're doing.”

You need to have an efficient operation first, and that is about process starting with the people who are:

- Designing - In Alignment w/ Strategy, Other Functions, and a Viable Business Model

- Building - Including Integration of the Technology Tools

- Operating - Achieving Outcomes Using Established Processes and Tools

- Maintaining

- Improving - The Plan, Do, Check, and Act Cycle (PDCA)

These are all related, but they are different levels of work requiring different experiences and ways of thinking. Learn more about levels of work and Stratified Systems Theory (SST).

These are the last two key strategic questions that need to be answered for a contractor to sustainably grow the business.

SELF-EVALUATION

Evaluate your company as a whole, each functional area (estimating, accounting, etc.), and each individual team member starting at the top of the organizational chart.

- For each of the five process level categories above, how would you evaluate each on a scale of 0-10 and why?

- Is the evaluation appropriate for their role and stage of growth for your company?

An experienced and unbiased 3rd party can be invaluable for helping you evaluate your team and then design your organizational structure and processes to best support your strategies.

All relationships begin with a simple conversation.