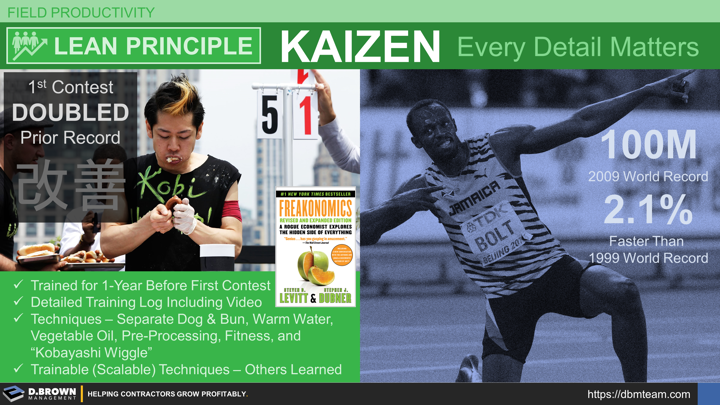

Takeru Kobayashi or Usain Bolt?

Who would you choose as a role model for improving your project, team, and business?

This question, though unconventional, is meant to illustrate two critical points:

- Attention to every detail and a focus on continuous improvements (Kaizen) are essential in any competitive environment - especially in construction, where competition is fierce.

- In mature competitive environments, such as Olympic sprinting, the gap between top performers is extremely narrow. However, construction is not yet a fully mature competitive environment, presenting significant opportunities for some contractors.

Quick Background (Olympics and Eating Contests)

The 1896 Summer Olympics were the first international Olympic Games held in modern history with athletic competition going back to our earliest recorded history.

Usain Bolt began competing in 2001, and in 2009, he set a world record for the 100 meters at 9.58 seconds. As of the end of 2023, this record still stands, making him 2.1% faster than the 1999 record of 9.79 seconds—a gap achieved over a span of 20 years.

The Olympic games generate billions of dollars in revenues and costs, with an economic impact that extends well beyond athletics, including significant brand influence. For a star athlete like Usain Bolt, their compensation is millions of dollars per year.

By contrast, Nathan's Famous International Hot Dog Eating Contest began in 1972. Feasting competitions have a long history in various cultures, where gluttony was often a symbol of strength and power.

Takeru Kobayashi also first competed in 2001, eating 50 hot dogs in 12 minutes—doubling the previous record from 2000. He continued to push this record until 2006, improving his performance by about 7.5%.

In 2008, the time constraint was lowered to 10 minutes and the new record set by Joey Chestnut in 2022 is 76, which is 1.7 times the production rate of Takeru's 2006 record.

The contest attracts 40K live spectators and 2M virtual viewers. By contrast, the Summer Olympic games sell about 6.5M tickets (160 times more) with another 3 billion viewers (1,500 times more). The financials for Nathan's and compensation for competitive eating are similarly unequal when compared to the Olympics and top athletes.

Training History (Usain & Takeru)

“We don't rise to the level of our expectations; we fall to the level of our training.” - Archilochus (650 BC) and often cited by Navy SEALs

There is plenty of information available on training of top athletes including their autobiographies. It is nearly incomprehensible to understand the magnitude of the body of knowledge around performance, the multitude of specialists used by top athletes, their training, diet, and recovery.

Relentless by Tim Grover who coached Michael Jordan, Kobe Bryant, and Dwyane Wade is a good starting point to understand the intentionality and intensity that goes into building a top athlete over decades. Another excellent resources is Winning Ugly by Brad Gilbert, one of Andre Agassi's coaches, where he describes attention to detail down to packing your bag. Special Operations has a similar level of selection and training process which Rich Diviney describes well in The Attributes.

The construction industry is nowhere near that level. Contracting is a highly fragmented market with about 1 million businesses largely figuring it out as they go along.

By contrast, Takeru was largely self-taught as detailed in the book Freakonomics. The resources, tools, and tactics he worked with are more akin to what the average contractor or person in the construction industry would have access to. Some of his key practices included:

- Spending a year training before his first contest.

- Keeping a detailed training log, including videos of his eating sessions.

- Experimenting constantly to figure out the optimum process, including sequencing—similar to PDCA Cycles, which only work if you have standards and feedback.

- Learned that pre-processing (think prefab) helped him eat faster; he used his hands to separate the hot dog from the bun and break the hot dog into pieces.

- Learned that soaking the bun in water made it faster to eat.

- Learned that warm water worked better than cold water.

- Learned that a little vegetable oil in the water worked even better.

- Maintained a high fitness level.

- Developed the "Kobayashi Wiggle" to help settle the food in his stomach faster while eating.

The techniques Kobayashi learned were trainable and scalable. They were able to be learned and used by others who continued to improve.

This last part is especially important for contractors as the talent shortage will continue to worsen through 2030.

Kaizen is a Japanese word meaning improvement. As part of the lean body of knowledge, it refers to the concept of continuously improving all business functions and involving all employees from CEO through the field.

It is called many other things, but the concept is the same.

Aggregation of marginal gains is another term and used by many sports teams from Olympic bicycle racing to the All Blacks rugby team. This concept involves breaking everything down to identify even the smallest improvements, such as making the bicycle chain 1% more efficient.

CRITICAL NOTE: Continuous improvement is foundational for Operational Excellence, but you can't continuously improve your way past poor strategic choices.

No amount of continuous improvement was going to allow the dominate horseshoe manufacturer to compete with Henry Ford.

Be cautious not to get caught up in incremental improvements that don't change the outcome or distract you from making tougher decisions around strategy, markets, and talent.

700% Return on Investment Example

Paul Akers (2-Second Lean) does a great job of demonstrating Kaizen and standards in this video. While it can seem monotonous to watch, pay attention to the continuous measurement and experimentation. The second video is an update showing where they got to after another few years of continuous improvement.

Observe how they use operational math, beginning with knowing it costs $0.25 per minute to self-perform a task. When compared to the cost of outsourcing, anything under three minutes per task is more profitable. This is the same mindset you would apply on the job site or in the office. The first question is whether you can self-perform competitively.

Their first timed experiment was 0:45 seconds—well under three minutes—but remember we have to factor in non-installation time like we do in construction. This is a secondary issue that is worth noting. They also paused to review some quality details and adjusted the standard.

Notice Paul's enthusiasm as he plants seeds, reinforces key metrics and concepts, and asks questions to develop the team. This is what It's the Manager: Moving from Boss to Coach embodies.

Even for a task as short in duration as this, he reinforces that it is still a series of much smaller movements. Saving a second on each one adds up to bigger savings for the total tasks. Seconds turn to minutes and minutes become dollars. Saving 10-minutes per day for a contractor with $15M in labor costs yields $500K in savings.

They designed the experiments as cheaply as possible to prove or disprove their ideas.

Not all ideas worked out, especially after the 8th iteration, they were undoing some things and some of the times actually slipped backwards. Progress is rarely linear, especially after the more obvious improvements have been made. This is why Usain Bolt's improvements were much smaller than Takeru Kobayahsi's.

The video shows 15+ iterations with likely three to five times that many behind the scenes. That's the persistence required for continuous improvement.

Of those that were timed in the video, over 20% went backward on the timing—highlighting how easy it is for people to become discouraged. This is why positive engagement from management is so crucial.

The result was a reduction in time from 0:45 seconds to 0:15 seconds each. At 150 units per day, this is a savings of 75 minutes per day.

What's the Return on Investment?

Assuming this experimentation took an entire day, involving multiple people, including a supervisor and a higher-level manager, the time investment could be estimated as follows:

- 480 minutes for the person doing the task.

- 480 minutes for their supervisor, multiplied by 1.5X to account for the pay differences (totaling 720 equivalent minutes).

- 480 minutes for the Manager Once-Removed (MOR), who has broader context, deeper experience, and can allocate more resources, multiplied by 3X (totaling 1,440 minute equivalents).

That's a total of 2,640 minutes or equivalent minutes, considering higher compensation for the manager and their manager or some other specialist. The return on Investment (ROI) calculation is as follows:

- Payback period: approximately 35 working days (2,640 minutes / 75 minutes per day)

- First-year return of 710%. based on saving 75 minutes per day across 250 working days per year, or 18,750 minutes total (312 hours). 18,750 / 2,640 = 710%.

Critical Assumption: There must be other work available for the person to complete during the time saved. This is the responsibility of supervisors and managers. If the savings do not result in extra total work being completed, then it is just waste.

Bigger Intangible ROI: The lessons learned by the front-line and supervisory team members can be applied to improve other areas of the business and train other team members.

Always do the math of prioritization.

Reflection Questions

What are the tasks that you do most frequently on your projects? Think in terms of units per year.

What would an exercise like this look like to improve those cycle times?